+91-9350180451 +91-7827552837 Call Now!

- Home

- Video Tutorial

- Courses

- Software

- Services

- 3D Printer

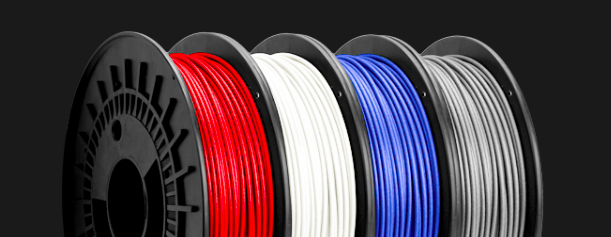

- Filaments

- 3DP Services

- Contact

🔹 2. ABS (Acrylonitrile Butadiene Styrene)

🔹 3. PETG (Polyethylene Terephthalate Glycol)

🔹 4. TPU / TPE (Thermoplastic Polyurethane / Elastomer)

🔹 5. Nylon (Polyamide)

🔹 6. PC (Polycarbonate)

🔹 7. HIPS (High Impact Polystyrene)

🔹 8. PVA (Polyvinyl Alcohol)

🔹 9. Carbon Fiber-Reinforced Filaments

🔹 10. Wood / Metal / Glow-in-the-Dark / Specialty Filaments

List of common types of 3D printing filaments used in FDM/FFF 3D printers, including their properties, uses, pros, and cons: